Reasons Why Every Manufacturer Needs a 3D Printer

We are currently living at an exciting time. Technology like the smartphone, for example, has enabled us to communicate with people we love, access information, take photos, navigate our way through cities, and a lot more with just a single device that fits in our pocket. But it’s going to be a lot more exciting as 3D printing technology becomes more mainstream. This is where practically anyone can print out solid 3D objects from designs they made on their computers or scanned using a 3D scanner. The applications are seemingly endless too. From consumer use to industrial to medical, 3D printing is a promising technology once its potential is finally unleashed.

But you don’t have to wait for the future to enjoy the benefits of 3D printing, especially if you are in the manufacturing business. In the list below we share with you a number of reasons why manufacturers need a 3D printer, starting with:

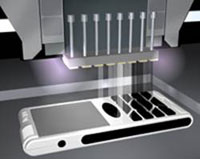

- Streamlines the design process. A typical process of printing a 3D object starts with a design on a computer, which results in a CAD file, which will then be the basis of the object to be printed. During the design process alone, you can already accomplish a number of tasks, such as checking for the form and fit, budgeting for the prototype and the production run, and a lot more. All these will enable you to save considerable time and money because you can make edits quicker without having to create an actual prototype.

- Speeds up prototyping. When the CAD file is finalised, you can then print out prototypes with your printer. This may take just a few hours depending on the type of material being used and the complexity of the design. After that, you or your customers will be able to review it faster, so you can tweak it further without having to wait weeks or months to do so.

- Makes creation of prototypes cheaper. Since you can already tweak the design on the computer, this eliminates the need for unnecessary printing of prototypes, especially when testing for form and fit. Your CAD program may also allow you to estimate the material needed to create the part and how much it will cost you, so you can make adjustments based on your budget.

- Enables you to manufacture at a small scale, affordably. Do you cater to a very specific market? 3D printing will enable you to create small production runs without the hefty costs of traditional manufacturing. This could enable you to put up a profitable business even without catering to the mass market.

Overall, 3D printers can revolutionise the way products are designed, prototyped, and manufactured. It can even enable businesses to provide replacement parts quickly and cheaply. At the moment, the possibilities are seemingly endless when it comes to this type of technology.